Stainless Steel Tank Dishes End Cap Dished Head

O.D. - Outside

Diameter I.D. - Inside Diameter

Thk. - Thickness (nominal or minimum)

Standard: DIN 315

Certification: ISO9001, SGS, ASME

Size range: 50mm-10000mm with integral formed,larger sizes with subsection formed can be specified

Thickness: 2mm-200mm

Material:stainless steel,carbon steel, aluminum,special steel etc.

Products DETAILS

Stainless Steel Tank Dishes End Cap Dished Head

Stainless Steel Tank Dishes End Cap Dished Head

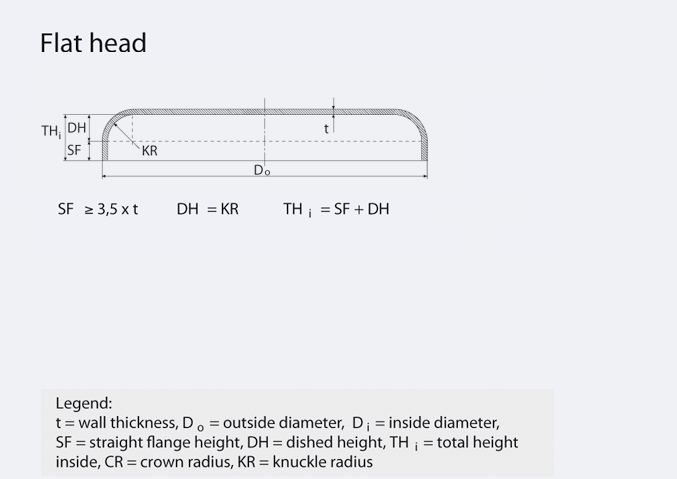

Flat Heads: These heads have flat surfaces, which makes them ideal for applications that demand flat inside surfaces. Flat heads are considered ideal for no pressure applications, when used for pressure applications, these pressure vessel heads may be quite expensive than other heads discussed here. This is why flat heads are mainly used for holding tanks or storage tanks that store materials at no pressure. These heads are also recommended in applications where lower head heights than ASME F&D heads are needed.

1. Production Specification

|

Forging part

|

Dish heads / ASME heads

|

|

Material

|

SA240T304/304L, SA240T316/316L, SA240T304H

|

|

Dimension

|

According to your drawings

|

|

Application

|

Pressure vessel/ Metallurgical industry

|

|

Inspection

|

Chemical composition; UT , MT; mechanical property; dimension check

|

|

Standard

|

ASTM, ASME, DIN, JIS, ISO, BS, API, EN

|

|

QC Doc.

|

Chemical composition report; mechanical properties report; UT test report; heat treatment report; dimensions check report.

|

|

Forging processing

|

Ingot---forging---heat treatment---rough machining---UT.MT---Q+T---inspection---finishing machining---UT.MT---Packing

|

|

Heat treatment

|

Normalized / Annealed / Quenched / Tempered

|

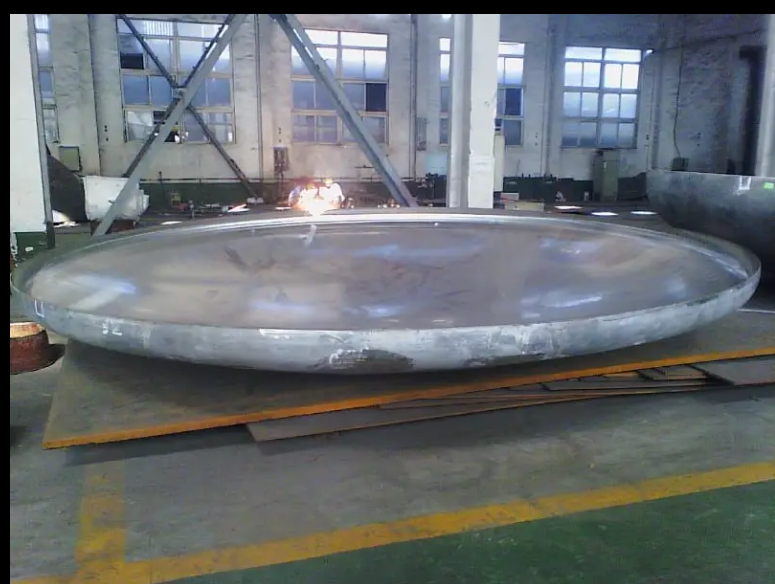

2. Production Drawing And Photos

|

Type

|

Specifications

|

|

6,000 Tons Cold Formed Machine

|

Forming diameter range from φ1600 to 3400mm

|

|

4,100 Tons Cold Formed Machine

|

Forming diameter range from φ500 to 1700mm

|

|

Three-roller Symmetry Rolling Machine

|

Maximum Rolling capacity:W3000 and 50mm THK.

|

|

10 M Vertical Lathe

|

Chuck diameter:φ5000mm;

Max. turning dia. φ11000mm |

|

39,000 Tons Hot Formed Machine

|

Forming Elliptical heads maximum φ 6500 x 300mm Thickness

(In one piece) Forming Hemisphere heads maximum φ 5600x280mm Thickness |

|

Trolley Type Natural Gas Heating Furnace

|

The dimension:10.5 meter * 10.5 m * 3.5 m

|

|

Automatic Sand Blasting Machine

|

Maximum Sand Blasting capacity : Diameter 5.7meter

|

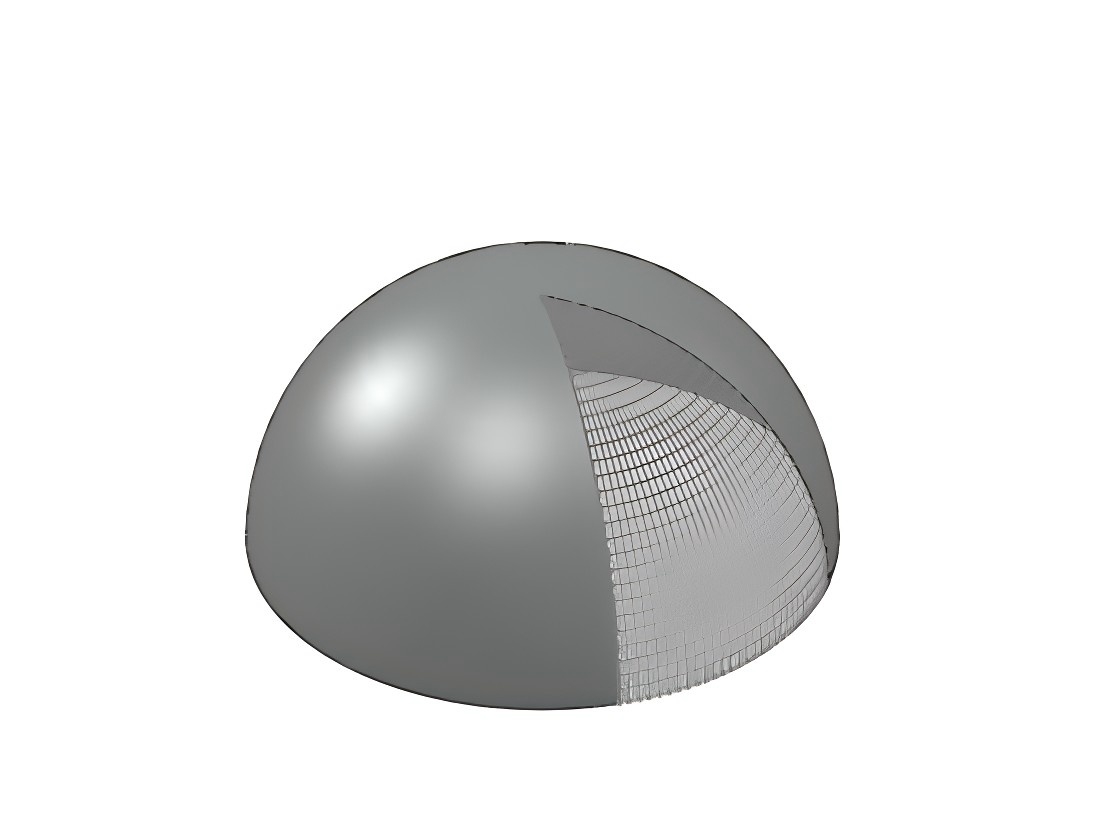

PRODUCTION

1,000-8,000t heat molding equipment,and 15 sets of cold spinning machines with the diameter 800 to 8500mm,3 sets of 3000t ball-petal press,and the matched aided detection and thermal treatment equipment,which can make the special abnormal heads of all materials,with the diameter of 51-7,500mm and the thickness of 3-500mm,as well as the melon petal heads with all kinds of diameters.All of its performance have reached and advanced the GB150-2011 and the American ASME Standards.The forming will according to customers requirments or the heads' specification.

Company Profile:

Welcome to Shandong Dayou Industry Co.,Ltd, a premier metal products manufacturing facility dedicated to delivering top-quality solutions for a diverse range of industries. The company can manufacture oval, dish, hemispherical, spherical (no straight edges), conical, pipe caps, expansion joints, flat-bottomed heads and various materials with diameters from 25mm to 11000mm and thicknesses from 1.0mm to 80mm. Special material and special-shaped head. The products are sold all over the worlds and are widely used in petrochemical,electric power, energy, machinery, pharmaceutical, food, environmental protection, water treatment and other industries.Our state-of-the-art facility is equipped with cutting-edge technology and staffed by a team of highly skilled professionals committed to excellence in every project we undertake.

The main equipment includes one 10000T, 5000T, 2000T, 1000T, 315T, 250T and 200T hydraulic presses, two 800T and 500T hydraulic presses, one set each of 4.2m, 7.2m and 11m drum spinning units, and a 2m spindle. It has one press, one 1.8-meter sphere spinning machine, two 3-meter spinning machines, multiple automatic welding and cutting equipment, and more than 60 supporting annealing furnaces, radiographic flaw detectors, physical and chemical testing and other auxiliary equipment ensuring that we meet the unique requirements of each client with precision and efficiency.. It is currently Top three in the country professional head manufacturers in China with a relatively complete range of equipment. Our comprehensive range of services includes metal stamping, CNC machining, welding, and finishing,

Our commitment to quality is reflected in our rigorous adherence to industry standards and our continuous investment in the latest manufacturing technologies. We pride ourselves on our ability to deliver custom solutions that not only meet but exceed the expectations of our clients. By fostering a culture of innovation and continuous improvement, we strive to remain at the forefront of the metal manufacture industry.

Related Products

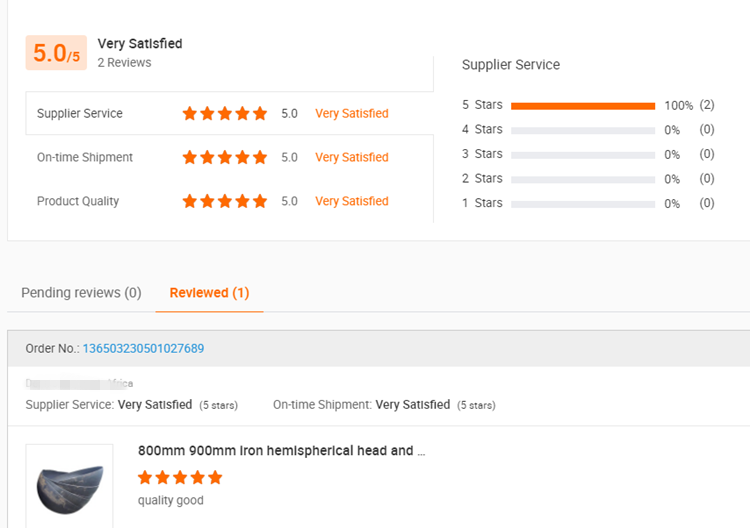

Customers Feedback About Our Large Metal Hemisphere

With over 15 years experience in this industry, we have cooperated with various customers from the whole world. And built an ongoing relationship with them already. Thanks to our quality control and producing team, and the support from our clients, we have won the good praise from them in various products including: hemisphere head, elliptical head, dish head, spherical head, flat head, conical head, BBQ firepit series.

Our Customers:

Payment and Shipping Methods

As a professional manufacturer and supplier for the tank heads, we support various payment and shipping methods.

We can take PayPal for the sampling order, and bank transfer, L/C for the bulk order.

We'd like to ship out the samples via DHL, Fedex, UPS, TNT, and ship out the mass production by boat.

As well as, we accpet various price terms and policies including EXW, FOB, CIF, CNF, DDP, DDU, DAP, ect.

Frequently Asked Questions

Q1. What is your terms of packing?

A: Generally, we pack our goods by plywood pallet , steel pallet or carton box. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 15 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8. What's the information should I provide when inquiry?

A. If you have drawings, we will be entirely in accordance with production drawings. If you do not have the drawing, you can tell me the product data. There are several important data, such as material, type of head, diameter, thickness, special tolerances or requirements. We can do the drawings according to your requirements, and you confirm that the final product drawings.

Q9. What are surface treatment of the product?

A. For carbon steel products, we sandblasting descaling product surface. For stainless steel products, we use acid to remove surface oil and impurities.

Q10. How do you ensure the quality of products?

A. Our production staff is trained through national quality department, and obtain the corresponding certificate, with years of production and design experience. Weld must undergo X-ray inspection to ensure that no defects.

Q11. Can you help us matching related products?

A. Our company also is surrounded by a lot of ancillary businesses, such as firepit bowls flanges, boiler, oil refining equipment, etc. We can help you matching the highest quality products with the lowest prices.