Formed Carbon Steel Elliptical Dished Head

Diameter: 12.7mm--10000mm

Thickness: 2mm--100mm

Material: Carbon steel/Alloy steel/Stainless steel

Surface Treatment: Sand Blasting, Transparent oil, Rust-proof oil, Galvanizing, Polishing

MOQ: 5 Pieces

OEM/ODM: Acceptable

Products DETAILS

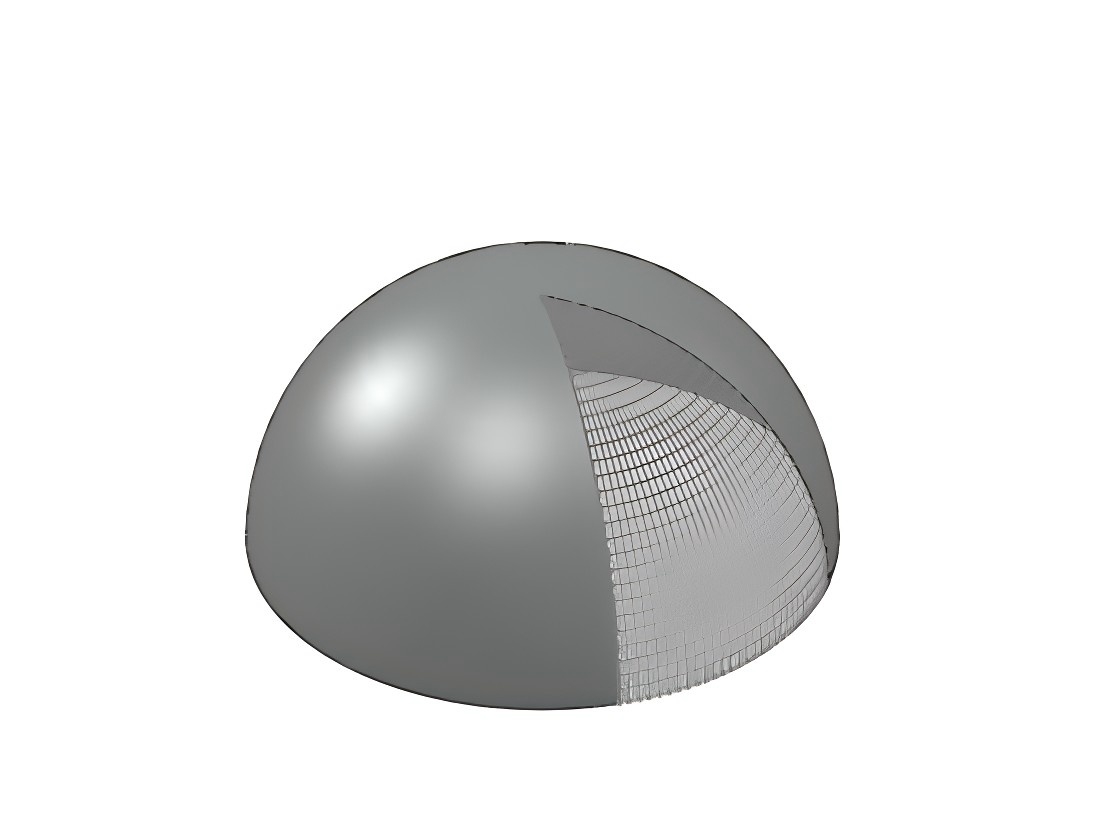

Formed Carbon Steel Elliptical Dished Head

|

Item |

Elliptical Heads

|

|

Product name |

Elliptical Heads |

|

Material |

Stainless Steel 304/316, Carbon Steel, Aluminium,Special Steel etc |

|

Color |

Natural |

|

Surface treatment |

Sand Blasting/Polished |

|

Thickness |

2mm-300mm |

|

Diameter |

89mm-1600mm |

|

Connection method |

Weldng |

|

Certification |

ISO9001, CE, ASME, CSA, SGS |

|

Standard |

ANSI, ASTM, DIN |

|

Application |

Such as oil, chemical industry, water conservancy, electric power, |

Ellipsoidal Head Specifications:

Ellipsoidal head is also called elliptical head or elliptical dish end. The shape of this ellipsoidal head is more economical,

because the height of the head is just a fraction of the diameter. The elliptical dish end radius varies between the major

and minor axis usually with the ratio is 2:1. The elliptical tank head is the economical solution for medium pressure tanks

due to the reduced metal thickness requirement.

Production Process of Heads:

Company Profile:

Welcome to Shandong Dayou Industry Co.,Ltd, a premier metal products manufacturing facility dedicated to delivering top-quality solutions for a diverse range of industries. The company can manufacture oval, dish, hemispherical, spherical (no straight edges), conical, pipe caps, expansion joints, flat-bottomed heads and various materials with diameters from 25mm to 11000mm and thicknesses from 1.0mm to 80mm. Special material and special-shaped head. The products are sold all over the worlds and are widely used in petrochemical,electric power, energy, machinery, pharmaceutical, food, environmental protection, water treatment and other industries.Our state-of-the-art facility is equipped with cutting-edge technology and staffed by a team of highly skilled professionals committed to excellence in every project we undertake.

The main equipment includes one 10000T, 5000T, 2000T, 1000T, 315T, 250T and 200T hydraulic presses, two 800T and 500T hydraulic presses, one set each of 4.2m, 7.2m and 11m drum spinning units, and a 2m spindle. It has one press, one 1.8-meter sphere spinning machine, two 3-meter spinning machines, multiple automatic welding and cutting equipment, and more than 60 supporting annealing furnaces, radiographic flaw detectors, physical and chemical testing and other auxiliary equipment ensuring that we meet the unique requirements of each client with precision and efficiency.. It is currently Top three in the country professional head manufacturers in China with a relatively complete range of equipment. Our comprehensive range of services includes metal stamping, CNC machining, welding, and finishing,

Our commitment to quality is reflected in our rigorous adherence to industry standards and our continuous investment in the latest manufacturing technologies. We pride ourselves on our ability to deliver custom solutions that not only meet but exceed the expectations of our clients. By fostering a culture of innovation and continuous improvement, we strive to remain at the forefront of the metal manufacture industry.

Package of Metal Tank Head:

1. Pallet packing

2. Wooden case packing

3. Steel pallet packing

4. Nude packing

5. According to customers' requirement

FAQ:

Q: What information should I provide when making an inquiry?

A: If you have production drawings, we will strictly follow them. If not, you can provide the product details, such as: Material ,Type of head (e.g., elliptical, hemispherical, dished, flat, etc.)Special tolerances or requirements

If needed, we can create drawings based on your specifications, and you can confirm the final product design before production.

Q: What information should I provide when making an inquiry?

A: If you have production drawings, we will strictly follow them. If not, you can provide the product details, such as: Material ,Type of head (e.g., elliptical, hemispherical, dished, flat, etc.)Special tolerances or requirements

If needed, we can create drawings based on your specifications, and you can confirm the final product design before production.

Q: What surface treatments are available for the product?

A:For carbon steel products: We perform sandblasting to remove surface scales.

For stainless steel products: We use acid treatment to eliminate surface oil and impurities.

Q: How do you ensure product quality?

A: Our production staff are certified by the national quality department and have extensive experience in production and design. Additionally, all welds undergo X-ray inspections to ensure they are free of defects.

Q: Can you help us source related products?

A: Yes, our company works with several nearby ancillary businesses, including suppliers of flanges, boilers, and oil refining equipment. We can help you source the highest quality products at competitive prices.