Comparison of Cold and Hot Forming Characteristics for Head Manufacturing

Upload Time:

Dec 09, 2024

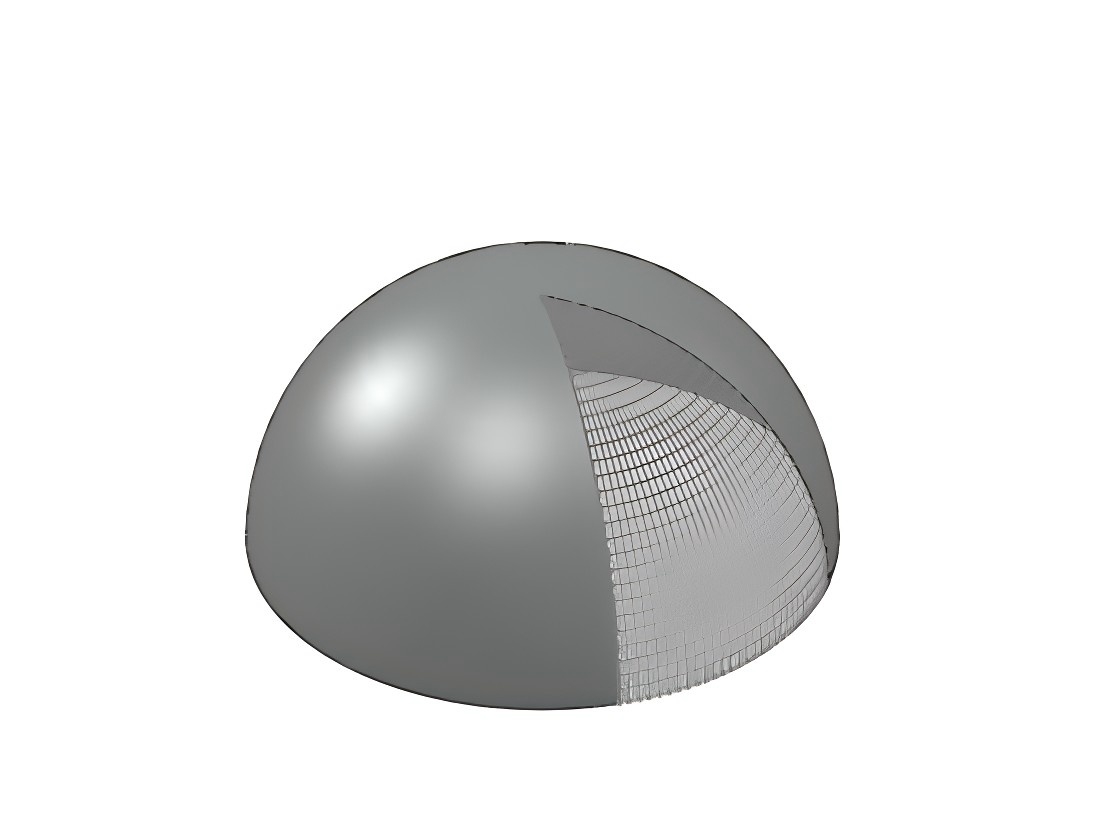

Cold forming and hot forming processes is different for head manufacturing.

This article compares the characteristics of cold forming and hot forming processes for head manufacturing.

Material Integrity

Cold forming does not require heating, thus preventing material degradation, which is especially important for stainless steel heads. In contrast, hot forming involves heating, which can cause material deterioration and reduce the corrosion resistance of stainless steel heads, making it unsuitable for such applications.

Dimensional Accuracy and Consistency

Cold forming, being a process that does not involve heating, avoids issues like cooling shrinkage, ensuring that the shape remains clear and neat, with precise dimensions and excellent consistency. On the other hand, hot forming leads to the expansion of the mold and cooling shrinkage of the head, making it harder to control the size and resulting in lower consistency.

Surface Finish

Cold forming maintains the original smooth and aesthetically pleasing surface of the head after shaping. In contrast, hot forming causes significant scaling on the surface of the head, which is difficult to remove, compromising the appearance.

Material Integrity

Cold forming does not require heating, thus preventing material degradation, which is especially important for stainless steel heads. In contrast, hot forming involves heating, which can cause material deterioration and reduce the corrosion resistance of stainless steel heads, making it unsuitable for such applications.

Dimensional Accuracy and Consistency

Cold forming, being a process that does not involve heating, avoids issues like cooling shrinkage, ensuring that the shape remains clear and neat, with precise dimensions and excellent consistency. On the other hand, hot forming leads to the expansion of the mold and cooling shrinkage of the head, making it harder to control the size and resulting in lower consistency.

Surface Finish

Cold forming maintains the original smooth and aesthetically pleasing surface of the head after shaping. In contrast, hot forming causes significant scaling on the surface of the head, which is difficult to remove, compromising the appearance.

Relevant News