Is the elliptical carbon steel head material resistant to high temperature?

Upload Time:

Dec 09, 2024

Oval carbon steel head is a special material commonly used for connecting containers and pipelines

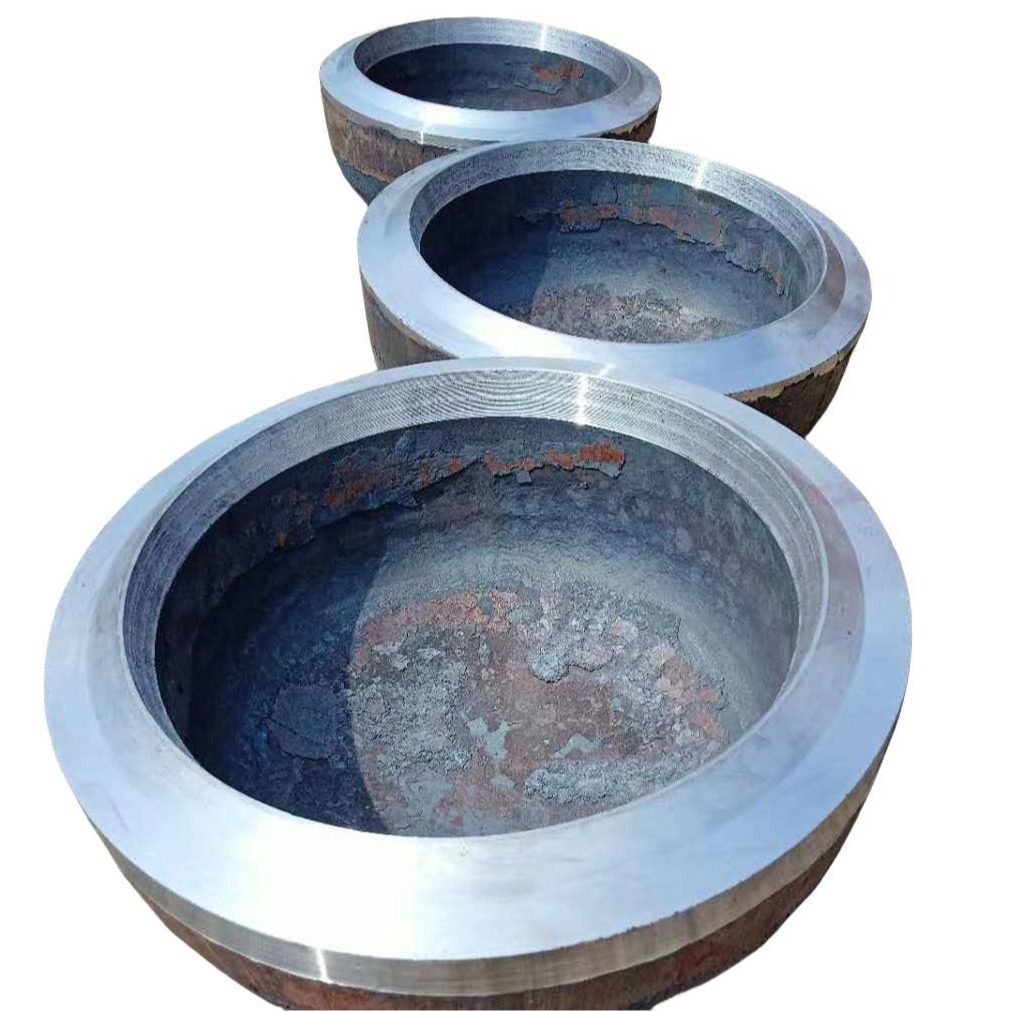

First of all, we need to understand the main components of elliptical carbon steel head. Oval carbon steel head is generally made of carbon steel, alloy steel and other materials. Carbon steel is an alloy with a high carbon content. Its main components are carbon and iron, and it also contains a small amount of silicon, manganese, sulfur, phosphorus and other elements. It has the cutting performance of general low-alloy steel, but poor weldability, especially relatively poor high temperature resistance. Therefore, in general, the corrosion resistance of carbon steel head in high temperature environment is low.

However, if the elliptical carbon steel head is treated as a special material, its high temperature performance can be improved. Special materials are made by special treatment of raw materials to change their organizational structure and chemical composition so that they have corrosion resistance and high temperature resistance. Special materials can generally be obtained through processing, quenching, solution treatment and other methods.

In the process of high-temperature resistant special materials processing, there are mainly the following links.

1. Raw material selection.

When selecting raw materials, you can choose some materials with high heat resistance, such as Cr-Ni alloy steel, Mo alloy steel, etc. These materials have high high-temperature oxidation resistance and corrosion resistance, and can maintain stable chemical and physical properties under high temperature environment.

2. Heat treatment.

Heat treatment is to change the crystal structure of the material to make it have better high-temperature performance. Common heat treatment methods include solution treatment, normalizing, quenching, etc. Solution treatment is to heat the material to the required temperature, keep it for a period of time, and then cool it quickly so that the solid solution in the material precipitates more uniform elements. Normalizing and quenching are to change the hardness, toughness and high temperature resistance of the material by heating and cooling the material.

3. Passivation treatment.

Passivation is to improve its corrosion resistance by forming a passive film on the surface of the material. Common passivation methods include pickling, electrochemical polishing, etc. These methods can remove the oxide scale and impurities on the surface of the material, forming a dense, smooth and uniform passivation film, and improving the corrosion resistance of the material.

Through the above special treatment, the high temperature resistance of the elliptical carbon steel head can be improved to a certain extent. Special material treatment can make the carbon steel head have better oxidation and corrosion resistance, and maintain stable physical and chemical properties under high temperature environment. Special material carbon steel head can not only resist high temperature oxidation and corrosion, but also maintain good mechanical strength and comprehensive performance. Therefore, in some harsh working environments such as high temperature and high pressure, special material carbon steel head is a good choice.

In general, the elliptical carbon steel head is a common connection material with poor high temperature resistance. However, through special material treatment, the high temperature performance of the elliptical carbon steel head can be greatly improved. Special material treatment can improve its high temperature resistance and corrosion resistance by selecting appropriate raw materials, heat treatment and passivation treatment. Therefore, when choosing an elliptical carbon steel head, you can consider choosing a product that has been treated with special materials to meet the use requirements in a high temperature environment.

Relevant News