Conical Head

Upload Time:

Dec 10, 2024

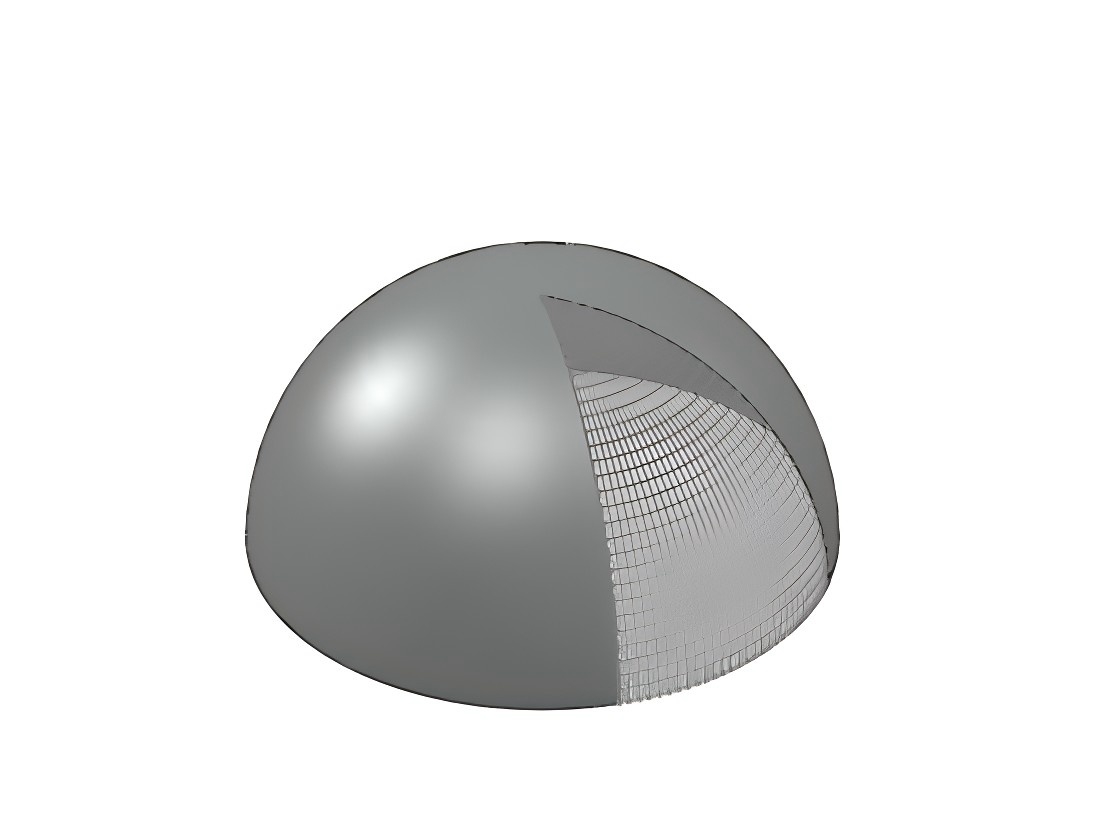

Conical heads come in different shapes, sizes, and purposes

The conical head is a critical component widely used in various types of containers. It serves as an essential structural element in the container, typically welded at both ends to seal or transition between sections. The design and manufacturing quality of the conical head directly affect the safe and reliable operation of the container over time. Therefore, understanding the design process and factors influencing the conical head’s performance is crucial.

Conical heads come in different shapes, sizes, and purposes, including oval heads, spherical crown heads, dish heads, cone heads, and flat caps. Oval heads are commonly used in many applications, particularly in pressure vessels for normal, medium, and low-pressure conditions. Spherical crown heads are often used in the middle sections of vessels with two independent pressure spaces or at the ends of vessels designed for lower pressures.

This article focuses on the conical head, which is typically used to connect two sections of cylinders with different diameters, serving as a transitional component. This is commonly referred to as a variable diameter section. Typical applications include pig receivers, reboilers, and towers.

Types of Conical Heads

The design of conical heads follows the relevant guidelines set out in GB150 "Pressure Vessel," which primarily addresses axisymmetric cone-shaped heads, either with or without flanges, and with a half-apex angle α ≤ 60°. GB150 further categorizes conical heads based on factors such as the thickness of the cone and whether the large or small ends are folded.

Common types of conical heads used in engineering include:

Non-folded conical shells of uniform thickness

Multi-section conical shells with the same half-apex angle but varying thicknesses

Conical shells with folded edges or straight sections at the large or small end

Conical shells with a reinforced section at the large or small end

During the design process, the specific type of conical head required is determined based on the actual engineering parameters and through detailed calculations to ensure it meets the strength and operational requirements of the vessel.

Relevant News