How to choose suitable hemispherical polished head ?

Upload Time:

Dec 10, 2024

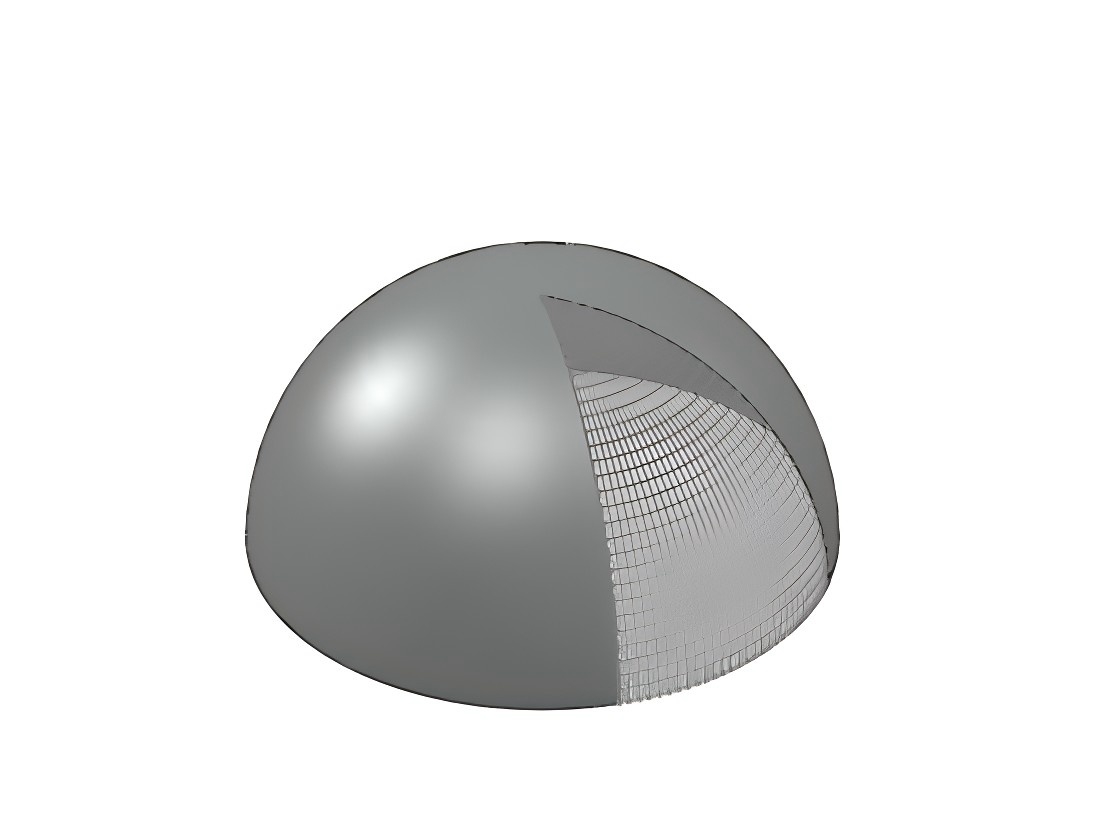

Hemispherical polished head is a commonly used pressure vessel component, widely used in chemical, pharmaceutical, food and other industries.

Hemispherical polished head is a commonly used pressure vessel component, widely used in chemical, pharmaceutical, food and other industries. It is characterized by simple structure, mature manufacturing process, good sealing performance, and can withstand high pressure and high temperature. When choosing a hemispherical polished head, the following factors need to be considered:

1. Material selection: Common hemispherical polished head materials include stainless steel, carbon steel, aluminum alloy, etc. Stainless steel has the advantages of good corrosion resistance and high strength, and is suitable for a variety of working conditions; carbon steel is relatively cheap, but it is easily affected by corrosion and needs regular anti-corrosion treatment; aluminum alloy is light and has good thermal conductivity, and can also play an important role in some special occasions. Choose the appropriate material according to the specific use environment and requirements.

2. Size and shape: The size and shape of the hemispherical polished head need to match the design requirements of the container. The size includes diameter and wall thickness. The diameter is generally twice the inner diameter of the container plus the wall thickness. The wall thickness needs to be calculated according to the working pressure of the container. The shape can be a standard hemispherical shape or a non-standard shape customized according to specific needs, such as an ellipse, a combination of a hemisphere and a cylinder, etc. Choosing the right size and shape can ensure that the hemispherical polished head is tightly connected to the container and meets the strength requirements.

3. Polishing requirements: The surface polishing of the hemispherical polished head directly affects its cleanliness and hygiene in use, especially in the food, medicine and other industries. Generally speaking, the higher the polishing degree, the smoother the surface, the smaller the flow resistance to the fluid, and the easier it is to clean the container. The polishing degree can be measured by the Ra value. The smaller the Ra value, the smoother the surface. According to specific needs, select the appropriate polishing requirements.

4. Sealing performance: The sealing performance of the hemispherical polished head has an important impact on the safety of use and operation effect of the container. When selecting a hemispherical polished head, it is necessary to consider its connection method with other components and the selection of sealing materials. Common connection methods include butt welding, flange connection, threaded connection, etc., and the sealing materials can be rubber, polytetrafluoroethylene, etc. Ensure that the connection is tight and the seal is reliable to avoid leakage.

5. Manufacturing process: The manufacturing process of the hemispherical polished head includes hot stamping, cold stamping, welding, etc. The hot stamping process has a low cost, but has high requirements for materials and is prone to deformation; the cold stamping process has a high cost, but has high manufacturing precision and is suitable for occasions requiring high precision; the head manufactured by the welding process has good integrity and strength, but attention should be paid to the quality of the weld. Choose the appropriate manufacturing process according to the specific situation.

In summary, to choose a hemispherical polished head that suits your needs, you need to consider factors such as material selection, size and shape, polishing requirements, sealing performance and manufacturing process. Only on the basis of fully understanding your own use environment and requirements can you choose a suitable hemispherical polished head to ensure the safe operation of the container and the quality of the product.

If you want to be simple, please feel free to contact us at any time.

Relevant News