Cone Shell Structure Design

Upload Time:

Dec 11, 2024

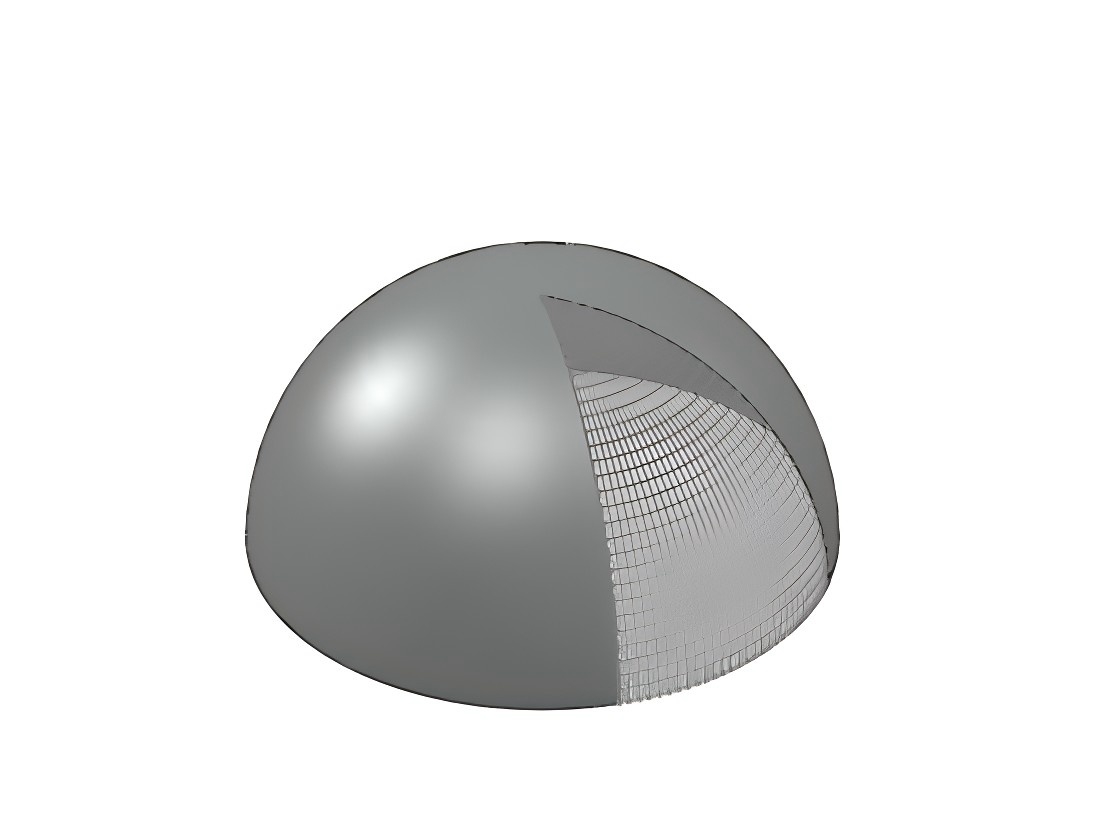

Conical heads come in different shapes, sizes, and purposes

When designing the structure of a conical head, the first step is to determine the required half-apex angle. Based on this angle, it is then decided whether the cone head should incorporate a flange. The design considerations are as follows:

- For a half-apex angle (α) ≤ 30°, both the large and small ends of the conical head can utilize unfolded cone shells.

- For 30° ≤ α ≤ 45°, the large end should be folded, while the small end may remain unfolded if the strength calculations are satisfactory.

- For 45° ≤ α ≤ 60°, both the large and small ends of the conical shell must have folded edges.

- For α > 60°, flat heads are typically used, or a stress analysis should be conducted to determine the design.

1. Eccentric Cone Shell

Some equipment, such as reboilers and pig receivers, requires eccentric cone shells. These are special cone-shaped structures used to connect two cylinders with parallel axes but different diameters. When designing such shells for equipment subject to internal pressure, the included angle between the eccentric cone shell and the cylinder should not exceed 30°. Additionally, the difference between the axes of the two cylinders should be no more than half the difference in their diameters.

2. Calculation of Conical Head

Due to the geometric change at the connection between the conical head and the cylinder, the radius of curvature varies, leading to lateral thrust. This generates higher edge stress, making the cone more susceptible to bending. Therefore, in the design process, it is crucial to calculate not only the thickness of the conical head but also to check whether the connection between the cone head and the cylinder requires reinforcement.

3. Reinforced Design of Cone Shell

The connection between the cone shell and the cylinder must be evaluated to determine if reinforcement is necessary. GB150 provides a reinforcement diagram that helps assess whether the connection requires additional strengthening. The key factors influencing this determination include the half-apex angle of the cone shell, the internal pressure, and the allowable stress of the material used at the design temperature.

In practice, adjustments to the half-apex angle or material selection can be made to meet specific design requirements. If the cone shell thickness needs to be increased for reinforcement, a reinforced section should be added at the junction between the cone shell and the cylinder. The thickness of this reinforcement should match the thickness of the cylinder reinforcement section.

4. SW6 Conical Shell Calculation

SW6 software simplifies the calculation of conical head design by allowing the user to input key parameters such as design pressure, design temperature, cylinder diameter, and material selection. This software helps assess whether the cone shell requires reinforcement and provides the necessary thickness and length for reinforcement.

For example, in a typical reboiler cone design:

- The required length of the small end reinforcement section is 39.23 mm, with a calculated thickness of 2.70 mm.

- The required length of the cylindrical reinforcement section is 36.71 mm, with a calculated thickness of 2.70 mm.

- The required length of the large end reinforcement section is 84.39 mm, with a calculated thickness of 3.10 mm.

5. Manufacturing of Conical Head

Due to the unique structure of the conical head, its manufacturing process differs from other types of heads. For tapered heads without folded edges, direct rolling is generally used to complete welding and stamping. For tapered heads with folded edges, a more complex process is required. Typically, a fan-shaped steel plate is used for blanking, which is then rolled into shape using a plate rolling machine and welded.

As an essential pressure component of containers, the structural design and verification calculations of the conical head are crucial. The thickness of the cone shell and the design of the reinforcement section are typically determined through auxiliary calculations using tools like SW6.

Relevant News