Best Methods for Cutting Metal Plates

Upload Time:

Dec 17, 2024

There are various cutting technologies available for processing stainless steel plates and metal sheets. Having all these cutting methods in one location is one of our key strengths. At our facility, we offer laser cutting, water jet cutting, CNC plasma cutting, and saw cutting.

Stainless Steel and Metal Sheet Cutting Solutions

There are various cutting technologies available for processing stainless steel plates and metal sheets. Having all these cutting methods in one location is one of our key strengths. At our facility, we offer laser cutting, water jet cutting, CNC plasma cutting, and saw cutting.

To help you select the most suitable cutting method for your stainless steel or metal sheets, this article highlights the benefits of each technique.

Laser Cutting

Our facility is equipped with multiple cutting centers, including advanced laser cutting machines that handle stainless steel sheets up to 3m x 6m in size and 30mm in thickness. CNC laser cutting is an exceptionally fast and precise process, delivering parts with a tolerance of +/- 0.5mm. This method is ideal for cutting steel plates and can produce holes with diameters equal to the sheet’s thickness.

Water Jet Cutting

Water jet cutting is one of our specialties, supported by dual-head cutting machines and high-pressure pumps. With a cutting capacity of 4.5m x 14m and a 5-axis cutting head for bevel cuts, we can process stainless steel sheets up to 200mm thick.

Water jet cutting is excellent for producing either rough drafts (faster cuts) or finished parts (slower, high-quality cuts), especially for thick stainless steel.

Tolerances range from +/- 1mm for quick cuts to +/- 0.15mm for precision, slow cutting.

Plasma Cutting

Plasma cutting marked the beginning of our cutting services and remains a highly effective method, particularly for blanks or pre-machined pieces. This technology can cut sheets up to 60mm thick with a maximum format of 3.5m x 8.5m.

Tolerances are +/- 1mm for thinner sheets and +/- 3mm for thicker sheets.

One limitation of plasma cutting is the presence of slag after cutting, which may require post-processing.

Saw Cutting

Our cold sawing equipment can process plates as large as 6,000 x 3,000 x 150mm. This method is heat-free, ensuring no thermal impact on the material. Saw cutting delivers tolerances of approximately +/- 1mm and is ideal for producing straight, rectangular cuts in stainless steel sheets.

Edge Machining – Chamfering

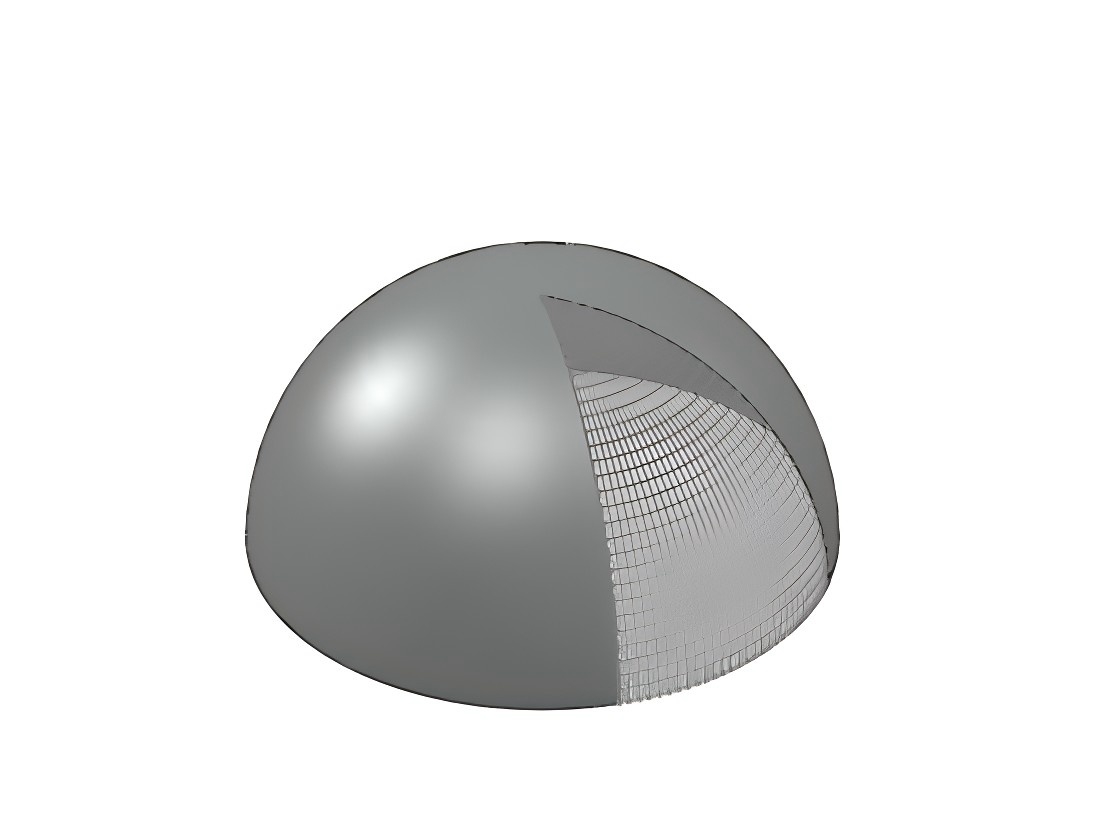

We also offer edge machining using a 5-axis cutting machine, allowing chamfering during the cutting process. The machine head can tilt at an angle of 45° relative to the vertical axis, providing clean, precise chamfered edges on stainless steel sheets.

Our comprehensive cutting solutions ensure that we can meet your project needs, regardless of the sheet size, material thickness, or desired finish.

There are various cutting technologies available for processing stainless steel plates and metal sheets. Having all these cutting methods in one location is one of our key strengths. At our facility, we offer laser cutting, water jet cutting, CNC plasma cutting, and saw cutting.

To help you select the most suitable cutting method for your stainless steel or metal sheets, this article highlights the benefits of each technique.

Laser Cutting

Our facility is equipped with multiple cutting centers, including advanced laser cutting machines that handle stainless steel sheets up to 3m x 6m in size and 30mm in thickness. CNC laser cutting is an exceptionally fast and precise process, delivering parts with a tolerance of +/- 0.5mm. This method is ideal for cutting steel plates and can produce holes with diameters equal to the sheet’s thickness.

Water Jet Cutting

Water jet cutting is one of our specialties, supported by dual-head cutting machines and high-pressure pumps. With a cutting capacity of 4.5m x 14m and a 5-axis cutting head for bevel cuts, we can process stainless steel sheets up to 200mm thick.

Water jet cutting is excellent for producing either rough drafts (faster cuts) or finished parts (slower, high-quality cuts), especially for thick stainless steel.

Tolerances range from +/- 1mm for quick cuts to +/- 0.15mm for precision, slow cutting.

Plasma Cutting

Plasma cutting marked the beginning of our cutting services and remains a highly effective method, particularly for blanks or pre-machined pieces. This technology can cut sheets up to 60mm thick with a maximum format of 3.5m x 8.5m.

Tolerances are +/- 1mm for thinner sheets and +/- 3mm for thicker sheets.

One limitation of plasma cutting is the presence of slag after cutting, which may require post-processing.

Saw Cutting

Our cold sawing equipment can process plates as large as 6,000 x 3,000 x 150mm. This method is heat-free, ensuring no thermal impact on the material. Saw cutting delivers tolerances of approximately +/- 1mm and is ideal for producing straight, rectangular cuts in stainless steel sheets.

Edge Machining – Chamfering

We also offer edge machining using a 5-axis cutting machine, allowing chamfering during the cutting process. The machine head can tilt at an angle of 45° relative to the vertical axis, providing clean, precise chamfered edges on stainless steel sheets.

Our comprehensive cutting solutions ensure that we can meet your project needs, regardless of the sheet size, material thickness, or desired finish.

Relevant News