Influence of Plastic Deformation on the Mechanical Properties of 304L Dish Head

Upload Time:

Dec 19, 2024

Plastic deformation during production and strengthening increases the yield strength of the 304L dish head and changes its wall thickness.

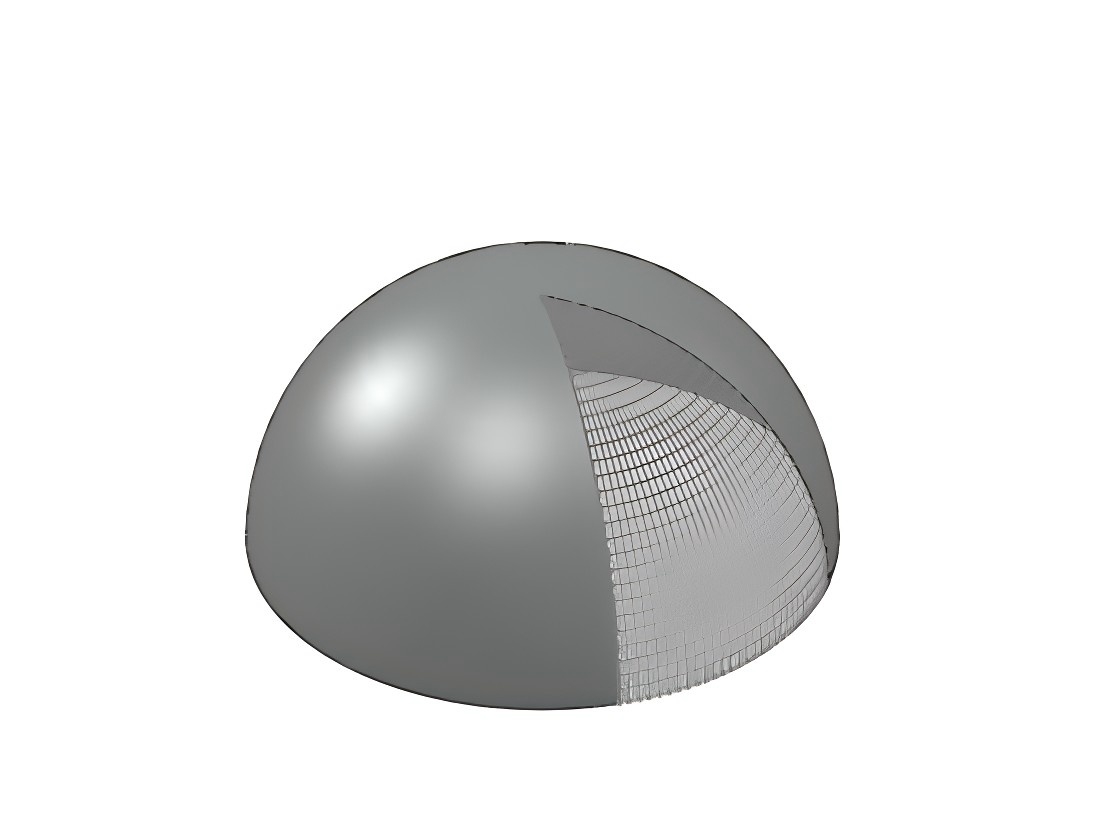

Plastic deformation in the 304L dish head of a pressure vessel occurs both during production and as part of the strain-strengthening process. Often, the plastic deformation that happens during production is overlooked, even though it can be significant, reaching up to 40%. Different parts of the head experience varying degrees of plastic deformation. The most noticeable effect is the variation in wall thickness: it is thinnest at the small arc, thickest at the straight side, and constantly changing along the large arc. The top area of the head also has a smaller wall thickness. Due to the substantial plastic deformation during forming, the mechanical properties of the head are affected, and 304L undergoes work hardening, which increases its yield strength.

Relevant News