Manufacturing Expansion Bellows for Industrial Applications

Upload Time:

Jan 13, 2025

The uses and applications of expansion bellows.

Why Are Expansion Bellows Such a Specialized Component?

The manufacturing of expansion bellows is one of our most intricate processes due to the numerous steps involved. In this article, we will explore the uses and applications of expansion bellows before delving into the details of the manufacturing process. You will discover what sets our approach apart and why we are globally recognized for our high-quality and consistent products.

Expansion Bellows Models

Expansion bellows are one of the most widely produced components in our facility, passing through multiple stages of production. Our specialized expertise and equipment for cutting, construction, metal shaping, heat treatment, and turning on lathes are key to producing the high-quality expansion bellows that have earned us international recognition.

We manufacture expansion bellows with diameters ranging from 500mm to 4,500mm and thicknesses of up to 25mm.

Uses and Applications of Expansion Bellows

Expansion bellows are primarily used in piping systems to absorb the effects of pressure, temperature, or vibration changes. A well-known application is their use in heat exchangers, where they are either installed within the exchanger or in the pipeline connections. In this role, expansion bellows absorb the movements caused by thermal contraction and expansion, as well as pressure fluctuations.

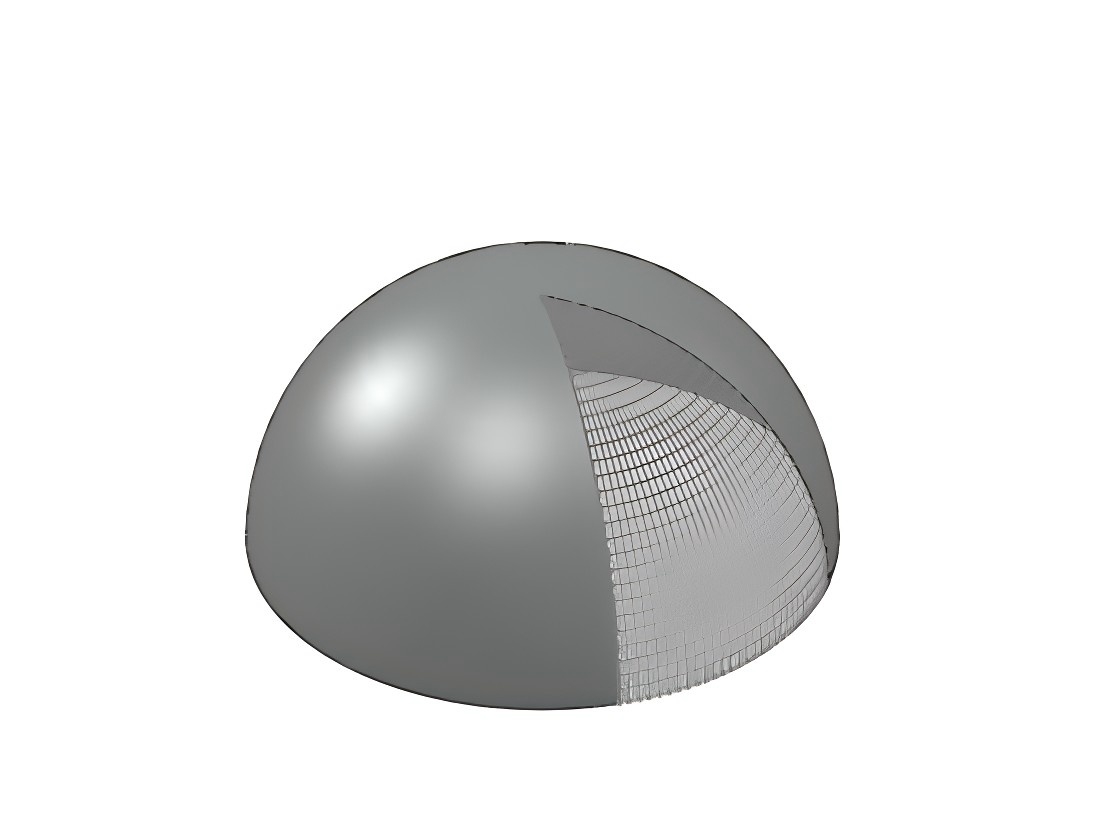

Typically, an expansion bellow consists of at least two identical parts, as shown in the image. Depending on the application, one or more sets of these half-bellows may be required.

While expansion bellows (also known as expansion joints) are used across various sectors, we focus specifically on manufacturing them for heavy industrial applications.

Custom Designs and Specifications

Typically, our clients provide us with precise drawings of the required expansion bellows, including the specific design codes for the entire installation. These drawings account for variables such as pressures, medium, temperatures, and vibrations, but most importantly, they specify the number of cycles the expansion bellows must endure—how many times they will need to contract and expand.

The manufacturing of expansion bellows is one of our most intricate processes due to the numerous steps involved. In this article, we will explore the uses and applications of expansion bellows before delving into the details of the manufacturing process. You will discover what sets our approach apart and why we are globally recognized for our high-quality and consistent products.

Expansion Bellows Models

Expansion bellows are one of the most widely produced components in our facility, passing through multiple stages of production. Our specialized expertise and equipment for cutting, construction, metal shaping, heat treatment, and turning on lathes are key to producing the high-quality expansion bellows that have earned us international recognition.

We manufacture expansion bellows with diameters ranging from 500mm to 4,500mm and thicknesses of up to 25mm.

Uses and Applications of Expansion Bellows

Expansion bellows are primarily used in piping systems to absorb the effects of pressure, temperature, or vibration changes. A well-known application is their use in heat exchangers, where they are either installed within the exchanger or in the pipeline connections. In this role, expansion bellows absorb the movements caused by thermal contraction and expansion, as well as pressure fluctuations.

Typically, an expansion bellow consists of at least two identical parts, as shown in the image. Depending on the application, one or more sets of these half-bellows may be required.

While expansion bellows (also known as expansion joints) are used across various sectors, we focus specifically on manufacturing them for heavy industrial applications.

Custom Designs and Specifications

Typically, our clients provide us with precise drawings of the required expansion bellows, including the specific design codes for the entire installation. These drawings account for variables such as pressures, medium, temperatures, and vibrations, but most importantly, they specify the number of cycles the expansion bellows must endure—how many times they will need to contract and expand.

This complex calculation is usually completed by the client’s process technology engineer. Our clients trust our expertise and experience, knowing we will deliver the high-quality, consistent products they require.

Relevant News