What are the different types of tank heads?

Upload Time:

Sep 29, 2023

The end tank head cap is actually a component used to close the end of the container to achieve the isolation requirement between the inside and the outside medium of the container, also called the end cap

The end tank head cap is actually a component used to close the end of the container to achieve the isolation requirement between the inside and the outside medium of the container, also called the end cap. The end cap of a cylindrical container is generally a rotating shell. According to the shape of its surface, it can be divided into convex, conical, flat and combined shapes. The so-called convex end cap refers to the end cap with a convex surface shape, such as hemispherical, elliptical, dish-shaped and spherical end caps without folding edges.

For example, in actual applications, we see that some gas cylinders use a combined bottom end cap with the convex surface facing inward, which not only meets the strength requirements, but also ensures safe use. This product is mainly used for various container equipment, such as storage tanks, heat exchangers, towers, reactors, boilers and separation equipment. The materials include carbon steel (A3, 20#, Q235, Q345B, 16Mn, etc.), stainless steel (304, 321, 304L, 316, 316L, etc.), alloy steel (15Mo3 15CrMoV 35CrMoV 45CrMo), aluminum, titanium, copper, nickel and nickel alloys, etc.

Combined with the current application situation, the head has become an indispensable and important component in pressure vessel equipment in many industries such as petrochemical, atomic energy, and food and pharmaceuticals. As the end cover on the pressure vessel, this component is a major pressure-bearing component of the pressure vessel, and its role is sealing. Therefore, it is an important component for actual production.

So what is the specific application situation? Usually, one is to use the head product as the upper and lower bottom of the tank-shaped pressure vessel, and the other is that when the pipeline reaches the end and is not going to extend forward, a head is used to seal the pipe by welding.

From this, it can be seen that there are actually some products that are close to the role played by the head at this time, such as blind plates and pipe caps, but those two products can be disassembled. After the head is welded, it cannot be disassembled. The matching pipe fittings include pressure vessels, pipelines, flanges, elbows, tees, crosses and other products. The quality of the head is directly related to the long-term safe and reliable operation of the pressure vessel.

According to different shapes, the heads can be divided into hemispherical heads, non-folded heads, elliptical heads, butterfly heads, conical heads and other types. What are the characteristics of different heads and what fields are they suitable for? Sida Head will give you a detailed understanding.

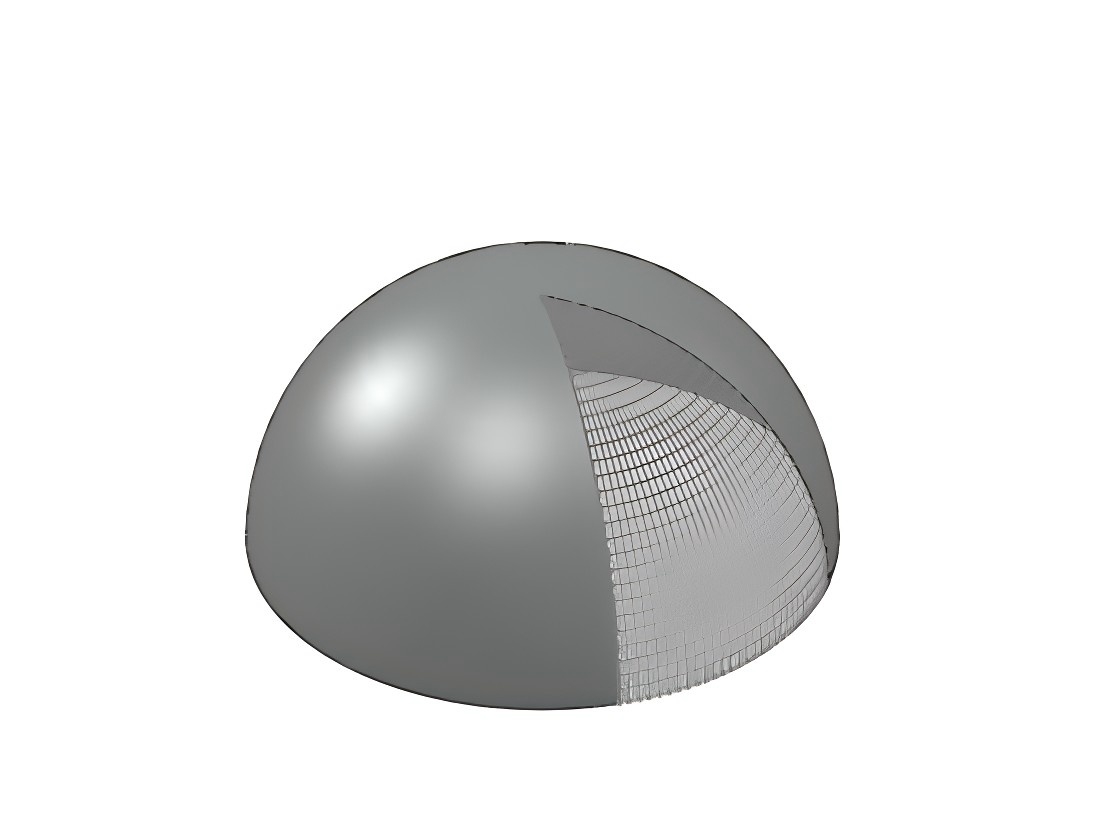

Hemispherical head

The hemispherical head is also called a spherical head. Its force structure is ideal and has a large depth. However, due to its relatively high manufacturing difficulty, it is generally only used for pressure vessels with high pressure and large diameter, and is rarely used in daily life.

Flat bottom head

The bottom surface of the flat bottom head is flat, the side is bent upward, the overall structure is simple, and the manufacturing difficulty is low, but the overall force of the flat bottom head is poor. Under the same pressure conditions, more thickness is required. The overall cost of the flat bottom head is low, and it is often used in containers with low pressure and small diameter.

Elliptical head

The elliptical head consists of half an elliptical surface and a cylindrical straight edge segment. It combines the advantages of good stress of the hemispherical head and shallow depth of the dished head. The warp curvature of the elliptical part is smooth and continuous, the stress distribution is uniform, and the overall performance is good. The elliptical head is currently a more commonly used type of head and is widely used in low-pressure containers such as storage tanks, reactors, and heat exchangers.

Butterfly head

The butterfly head is also called a spherical head with a folded edge. It consists of a spherical surface, a cylindrical straight edge and a transition part. The radius of curvature is smaller than the radius of the spherical surface. The dished head has a shallow depth, consumes less material, is easier to process, and has a lower processing cost. When the elliptical head is difficult to process, the dished head is generally used instead.

Conical head

The conical head consists of a conical shell, a transition arc, and a cylindrical straight edge segment. Due to its structural characteristics, it can evenly change the medium passing speed, which is convenient for unloading viscous liquids and solid particle materials. However, the mechanical properties of conical heads are poor, and the difficulty of manufacturing increases with the increase of wall thickness. Generally, they are only used when the process requires it.

Key points for the use of heads:

Heads are the main pressure-bearing components of boilers and pressure vessels. Whether their structure and shape design are reasonable affects the boilers and pressure vessels. Therefore, there are restrictions on the shapes of various heads in the relevant specifications.

Ellipsoidal heads Ellipsoidal heads are suitable for convex heads of boilers and pressure vessels, and standard ellipsoidal heads are preferred (Dn/hn=4). When non-standard ellipsoidal heads are used, the ratio of their major and minor axes shall not be greater than 2.5.

Dish-shaped heads Dish-shaped heads are spherical heads with folded edges. It has large bending stress, while ellipsoidal heads are mainly membrane stress, so they are not ideal in engineering use. When using a dish-shaped head, the corner radius of the head transition zone should be no less than 10% of the inner diameter of the head, and no less than 3 times the thickness of the head, and the inner radius of the spherical part of the head should not be greater than the inner diameter of the head.

There is a significant shape mutation at the connection between the spherical head without folding and the cylinder, which will produce a large additional bending stress. Therefore, it is only used in containers with small diameter and low pressure. When using a spherical head without folding, the inner radius of the sphere of the head should not be greater than the inner diameter of the cylinder.

Relevant News