What is the differences between conical heads and flat bottom heads?

Upload Time:

Dec 05, 2024

The conical head can change the speed of the medium evenly when it passes through, which is convenient for unloading viscous liquids and solid particle materials

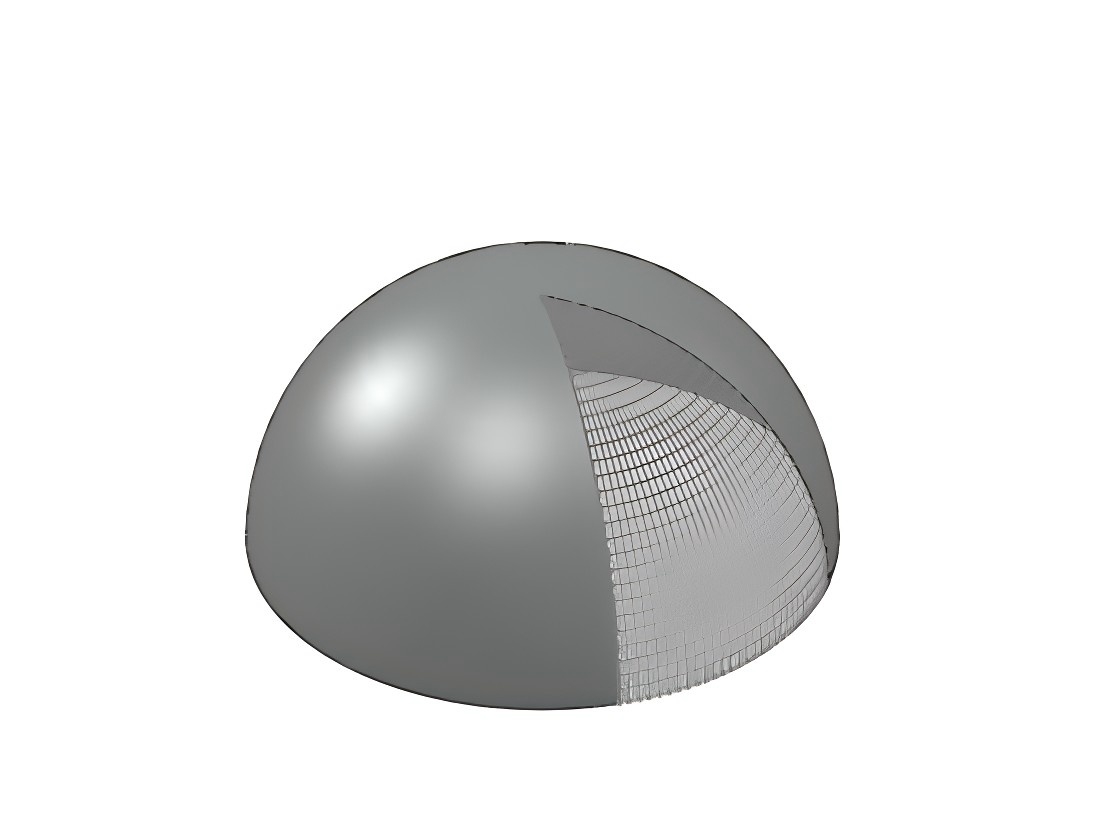

The conical head can change the speed of the medium evenly when it passes through, which is convenient for unloading viscous liquids and solid particle materials, but the mechanical properties are poor. The discontinuous stress generated by the sudden change of shape at the connection with the cylinder or the pipe is large. It is a head with a conical shell surface.

The flat bottom head is also a kind of accessory in the pressure vessel. It is mainly used for sealing. It is mainly formed by two methods: molding and spinning, but the effects are different. For example, the bottom flatness of the flat bottom head made by molding is relatively high, but the material size is large and the cost is relatively high. Although the flatness of the bottom of the spinning flat bottom head is a little lacking, it does not affect the general use, and the cost is low.

Therefore, most of them will adopt the latter method to make it directly on the spinning machine, but it should be noted that a splint at least twice as thick as the material should be added above and below the sheet to prevent deformation. The diameter of the flat bottom head is mainly determined according to the actual use requirements, and general requirements can be met.

The flat bottom head is also a kind of accessory in the pressure vessel. It is mainly used for sealing. It is mainly formed by two methods: molding and spinning, but the effects are different. For example, the bottom flatness of the flat bottom head made by molding is relatively high, but the material size is large and the cost is relatively high. Although the flatness of the bottom of the spinning flat bottom head is a little lacking, it does not affect the general use, and the cost is low.

Therefore, most of them will adopt the latter method to make it directly on the spinning machine, but it should be noted that a splint at least twice as thick as the material should be added above and below the sheet to prevent deformation. The diameter of the flat bottom head is mainly determined according to the actual use requirements, and general requirements can be met.

The material for manufacturing the conical head can be carbon steel, low alloy steel, composite plate, stainless steel, and non-ferrous metals such as copper, aluminum, and titanium.

Relevant News