What is a toriconical head?

Upload Time:

Dec 05, 2024

The conical head is a head with a spherical surface. The characteristic is that the medium can change the speed evenly according to the time, which is conducive to the removal of thick liquids and liquid-containing fine particle materials, but the physical properties are weak, and the discontinuous stress caused by shape mutations at the connection with the drum or transfer Very big. In order to reduce unsustainable stress, an arc-shaped flanged structure or partially thickened structure can be used at the big end or small end of the cone shell.

Material selection:

If the materials for manufacturing conical heads are alloy steel, high-alloy steel, sandwich panels, stainless steel, or rare metals such as copper, aluminum, titanium, etc., there are many national standards.

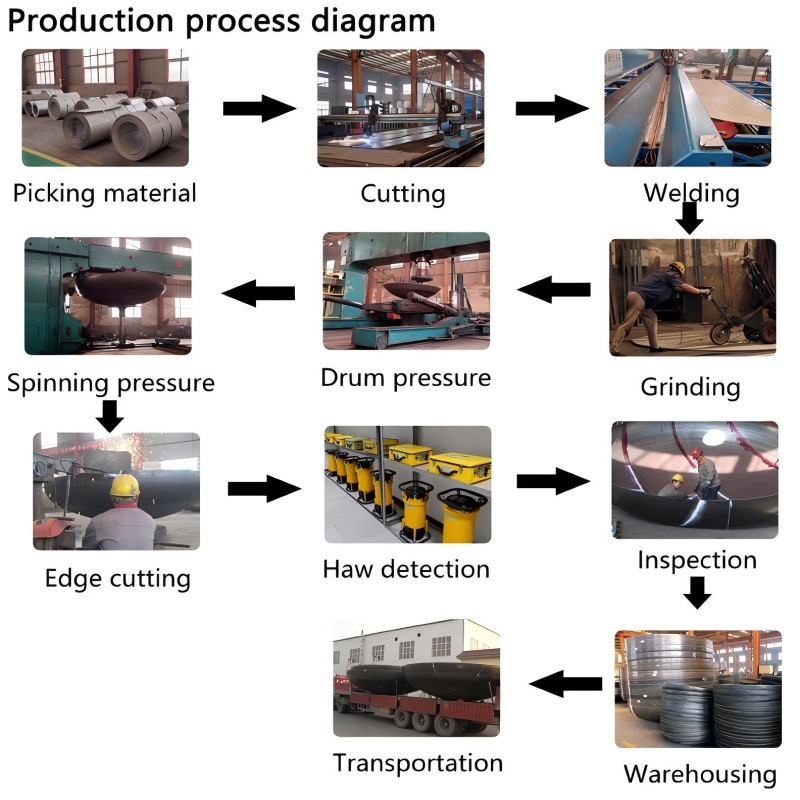

Production process:

The steps are: feeding - physical chemistry - cutting - hot forging - quenching and tempering - testing - deep processing - finished product inspection - marking - finished product inspection. The tapered head is used because its shape is a cone, and as a part of the main body, under the action of external pressure, the stress in the plastic film is generated at the big end. At the junction of the cone and the barrel, due to geometric discontinuity and sudden change in the radius of curvature, a large lateral thrust will be generated there, resulting in a large edge stress, which is prone to bending, so it needs to be improved.

The reason for the gap in the tapered head:

1. The raw material of the head is not up to standard;

2. The welding methods or welding materials used are unscientific;

3. The cold stamping process is unscientific.

Conical head According to your equipment, make the corresponding conical head, and then make a barrel according to the outer circumference of the conical head. When welding between the conical head and the barrel, the cone will be welded. Place the shaped head on the barrel, fix it at several points, touch weld it, and then slowly weld it together.

Scope of application:

1. As the main part of the cone-shaped head, under the action of external pressure, the largest stress on the film occurs at the big end. At the junction of the cone and the barrel, due to geometric discontinuity and sudden change in the radius of curvature, a large lateral thrust will be generated there, resulting in a large edge stress, and it is easy to bend, so it needs to be improved. For the big end, the radial bending stress is the main control factor, and it is a secondary geostress, so it is in addition to the geostress strength control;

2. For the small end, since the stress state at the junction between the small end and the barrel is mainly the average circumferential tensile stress and the average axial compressive stress, it belongs to the stress of the local plastic film, so the stress strength can be controlled In addition, since the geostress of some plastic films here may exceed the distribution range of the edge effect, for the sake of safety, the geostress strength is controlled within the range.

3. For the big end, the thickness of the lifting section should not be lower than the thickness of the connected cone shell under any circumstances, the distance between the lifting sections should be no less than that of the drum, and the distance between the lifting sections of the barrel should not be lower than the thickness of the connected cone shell. For the small end, under any circumstances, the thickness of the lifting section should not be lower than the thickness of the connected cone shell, the distance between the lifting section of the cone shell should not be lower, and the distance between the lifting section of the barrel should not be lower than that of the connecting cone shell.

Relevant News