How are pressure vessel heads made?

Upload Time:

Dec 06, 2024

The sealing head of a pressure vessel is an important part of the pressure vessel, and its sealing performance directly affects the safe operation of the entire container

1. Material selection: First, select the appropriate material to make the seal. Common materials include carbon steel, stainless steel, alloy steel, etc. When selecting materials, the temperature, pressure and chemical properties of the container operating environment should be considered.

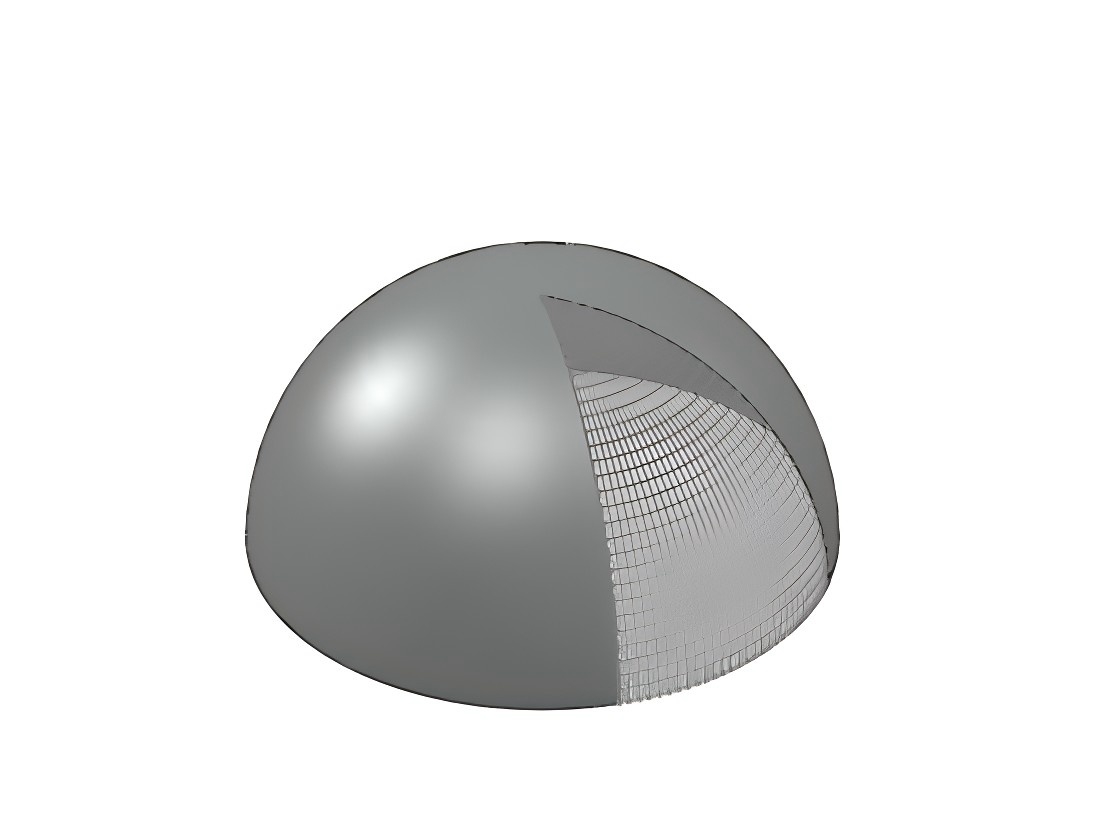

2. Dimension design: Determine the geometry, diameter and radius of the sealing head according to the design parameters and scale requirements of the container. Common sealing head shapes include round, oval, flat, etc. When selecting the shape of the sealing head, the convenience of loading and unloading, strength requirements and connection with other parts of the container should be considered.

3. Manufacturing process selection: Select a suitable manufacturing process according to the shape and material characteristics of the sealing head. Common sealing head manufacturing processes include cold stamping, hot stamping, hot forming, cold forming, sheet metal welding, etc. Different processes will affect the molding accuracy, surface cleanliness, strength, etc. of the sealing head

4. Manufacturing process control: During the manufacturing process, attention should be paid to quality control in each link. Including material quality inspection, size processing, process parameter control, etc., especially the surface quality of the sealing head, without obvious defects such as bumps, cracks, pores, etc.

5. Non-destructive testing: After the head is manufactured, non-destructive testing is carried out to ensure that the head has no internal defects such as cracks and inclusions. Commonly used non-destructive testing methods include ultrasonic testing, eddy current testing, and radiographic testing.

6. Strict quality control: During the entire manufacturing process, strict quality control includes formulating process flow, establishing process documents, setting quality inspection points, and formulating quality inspection standards. Ensure that the quality of the sealing head meets relevant standards and requirements

In summary, the manufacturing process design of the pressure vessel head needs to comprehensively consider factors such as material selection, size design, manufacturing process selection, manufacturing process control, and quality control. Only by reasonable design and strict control of each link can the quality and safety of the head be guaranteed, thereby improving the service life and safety performance of the entire pressure vessel. The pressure vessel sealing head is an important part of the pressure vessel. It bears the huge pressure and temperature inside the pressure vessel, and is sealed by connecting with the container body to ensure the safe operation of the container.

Relevant News